Copyright © Dongguan EMHEATER Electrical Equipment Co., Ltd. All Rights Reserved. Site Map

The requirements of Industrial washing machine for inverters:

1. VFD could provide high torque, multi-speed, wide voltage range, automatic slip compensation and convenient communication mode, with stable performance, VFD could adapt to high temperature and high humidity environment in various hotels laundry rooms.

2. VFD could adapt to the specific washing process requirements of industrial washing machines and service requirements for specific customer

groups.

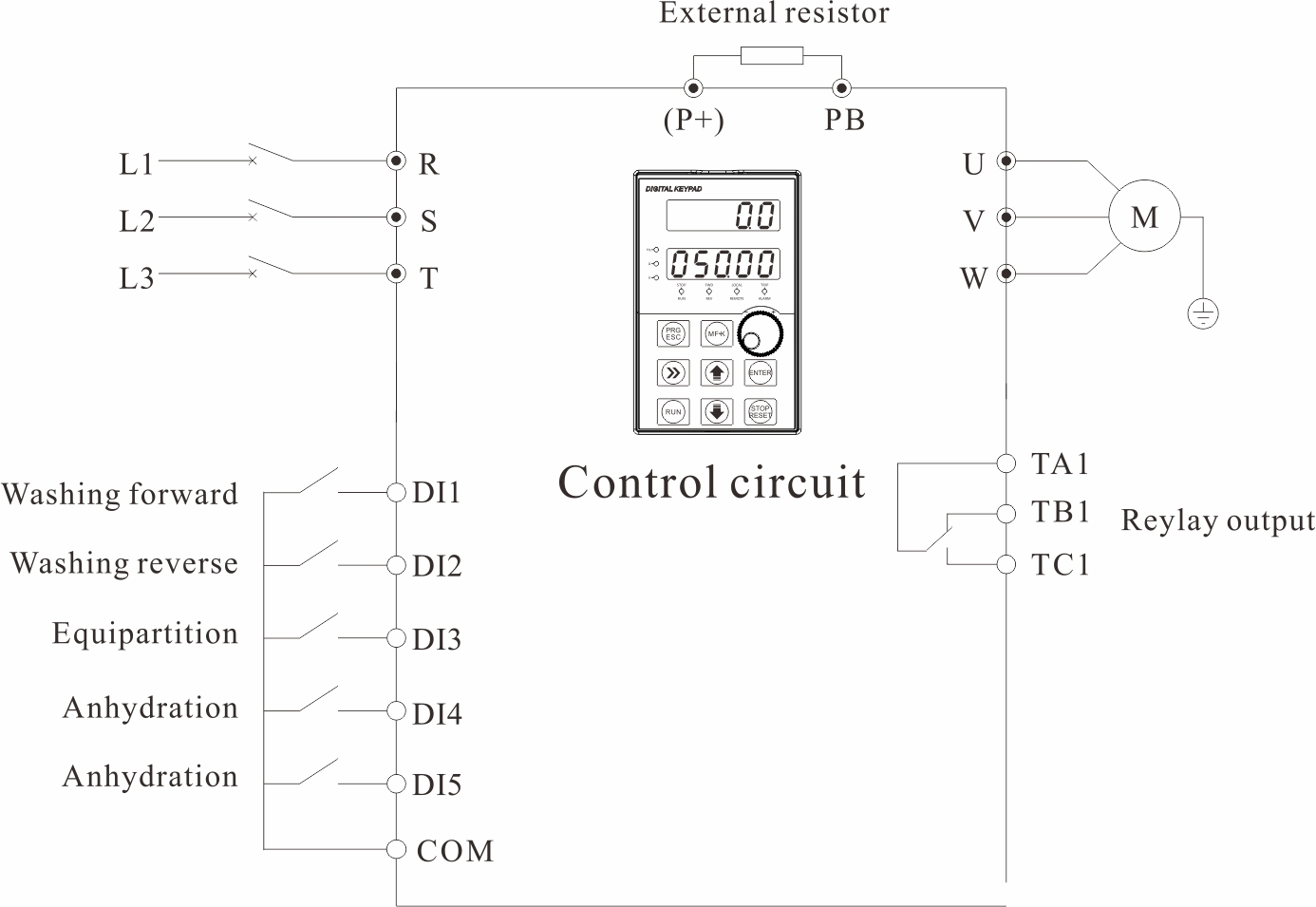

Wiring:

V / F curve user-defined of VFD is the most critical step in industrial washing machine application's debugging, the debugging process must be optimized according to the site conditions.

The main principles:

1. the start of Industrial washing machine should be slow and steady, the inverter's low-frequency starting torque should be large.

2. Please note the V / F curve slope, if each V/F curve set point slope is too large, it will cause the running current is too large. Or if the slope is too small, it will be too small to start. Therefore, it should be define according to the motor and its scene.

Attached: because of the special process requirements for the automatic industrial washing machine, generally, we will increase one or two power level of the inverter for washing machine, base on the its motor rated power.

Parameters setting:

code name setting Description Remark b0-01 Control mode 2 V/F control Factory default b0-02 Command source 1 External terminal control b0-03 Main frequency source X selection 6 Multi-speed function b0-13 Maximum frequency 120HZ Tuning according to the real requirement b0-15 Frequency upper limit 120HZ b0-21 Acceleration time 120s b0-22 Deceleration time 120S b2-03 Acceleration time 2 40S b2-04 Deceleration time 2 40S b2-13 Acceleration time 1 and time 2 switching frequency point 25.00HZ Run b2-03/b2-04 below 25HZ,Run b0-21/b0-22 above 25HZ b2-14 deceleration time 1 and time 2 switching frequency point 25.00HZ b3-00 DI1 function selection 1 forward Factory default b3-01 DI2 function selection 2 reverse b3-02 DI3 function selection 6 multi-function 1 b3-03 DI4 function selection 7 multi-function 2 b3-04 DI5 function selection 8 multi-function 3 C1-00 multi-function 0 6.25% 7.5HZ washing C1-01 multi-function 1 16.67% 20HZ equipartition C1-02 multi-function 2 66.67% 80HZ Medium anhydration C1-04 multi-function 3 100% 120HZ Heavy anhydration C1-00~C1-07 will be changing as different applications, When testing the machine, it needs to be adjusted according to the actual situation. d0-00~d0-04 Should be set according to motor’s nameplate d2-00 V/F curve setting 1 Multi point V/F curve d2-07 V/F frequency point3 50.00HZ Multi point V/F curve setting d2-08 V/F voltage point3 100.0% d2-05 V/F frequency point2 25.00HZ d2-06 V/F voltage point2 60.0% d2-03 V/F frequency point1 8.00HZ Improve low frequency torque,tuning d2-03 according to the real current during washing process d2-04 V/F voltage point1 30.0%

Notes: normally, the washing current will not over than 28A for 7.5KW washing machine. If it was over than 28A, V/F curve may be set inreasonable or wrongly motor parameters.

Applications pictures for reference:

Version:Ver2.0